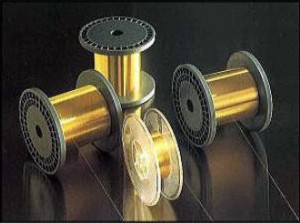

Suzuki SP Wire for Wire-EDM

SP Strong like tungsten

Conductive like Brass

Less Cost

Available from 0.03mm

SP Wire Structure and Specifications

SP Wire Structure and Wire Geometry

SP Wire Specifications

| Product code |

Wire OD (mm) |

OD tolerance (mm) |

Tensile strength (N/mm2) |

Outer shell thickness (avg) (micro m) |

Electric conductivity (%) |

|---|---|---|---|---|---|

| SP30S | 0.03 | +0.000

-0.003 |

2160=.< | 1.5 | 13=.< |

| SP40S | 0.04 | 2.0 | |||

| SP50S | 0.05 | 2.5 | |||

| SP60S | 0.06 | 3.0 | |||

| SP70S | 0.07 | 3.5 | |||

| SP80S | 0.08 | 4.0 | |||

| SP100S | 0.10 | +0.000

-0.004 |

1960=.< | 5.0 |

.

SP Wire Length/Reel and Reel Dimensions

| Length/reel(m) | Product applicable |

Type of reel | Reel dimensions(mm) | ||||

|---|---|---|---|---|---|---|---|

| Flange | Barrel | Traverse | Total length |

Bore | |||

| 20,000 | SP100S – SP50S | Type A | 130 | 80 | 90 | 110 | 20 |

| 10,000 | SP100S – SP40S | Type A | 130 | 80 | 90 | 110 | 20 |

| 5,000 | SP100S – SP30S | Type A | 130 | 80 | 90 | 110 | 20 |

| 5,000 | SP100S – SP30S | Type B | 130 | 60 | 30 | 37 | 13 |

.

SP Wire Cutting Characteristics and Performance

ED Cutting Performance of SP Wire

- Cutting speed

Improvement of ≥10% over tungsten wire, thanks to SP wire’s high electrical conductivity. - Surface roughness

Due to its excellent ED stability and high tensile strength, SP provides a fine surface roughness as good or better than that of brass wire. - Cutting width (clearance)

With its high tensile strength and stable ED characteristics, SP wire provides precise, fine ED cutting where the cutting width (clearance)is ≥20% narrower and the corner radius is smaller than that with tungsten wire. Thus, the same machining accuracy can be obtained with one size larger SP wire, along with a much faster cutting speed. - Abrasion of wire guides

Since SP wire is flexible and has a soft and smooth surface, abrasion of the wire guides (electrified pins, guide rollers, etc.) of ED machines is far less than that with tungsten wire, reducing operating costs. - Automatic wire joining

SP wire has excellent free cast and straightness, allowing a high rate of automatic wire joining. - Longer continuous length

SP wire provides a longer continuous length per reel: 5,000m/reel, 10,000m/reel and 20,000m/reel, while that of tungsten wire is 3,000 – 5,000m/reel. Thus, longer continuous operation and higher productivity can be achieved. - Surface stability

Unlike tungsten wire, SP wire is invulnerable to surface oxidation. Remaining wire can therefore be used again easily. - HOMO phenomenon

The HOMO phenomenon, an unstable ED caused by the short-circuit, that occurs when cutting a tungsten-containing work piece (e.g., tungsten carbide) with a tungsten wore, does not occur with SP wire. - Cost performance

In addition to the excellent properties above, SP wire is far less expensive than tungsten wore, providing an excellent cost performance - An easy method for setting cutting conditions

To find the optimum cutting conditions for SP wire, first set the cutting conditions for a brass wire electrode having a diameter equal to SP wire. Then gradually increase the wire tension until the SP wire breaks. The optimum tension is that just before breakage.

You may also be able to obtain SP wire cutting condition data from ED machine manufacturers.